This is an old revision of the document!

Devices

The Next Improve System in the production line

NIS is an acronym that stands for Next Improve System. NIS allows the control and monitoring of production efficiency, both in real time (Andon) and over a certain period (OEE).

How to Implement the NIS on-field

In order to implement a Next Improve System, you need the following devices:

- An LED TV (we recommend at least a 40 inches TV)

- A mini PC

- A Touch Panel

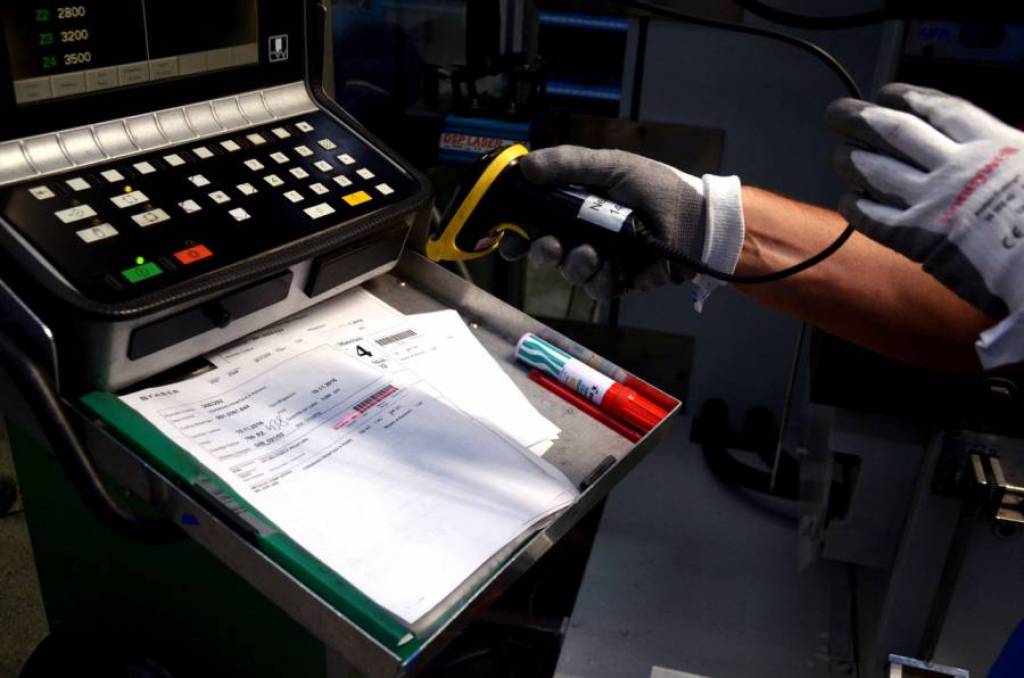

- A Barcode reader

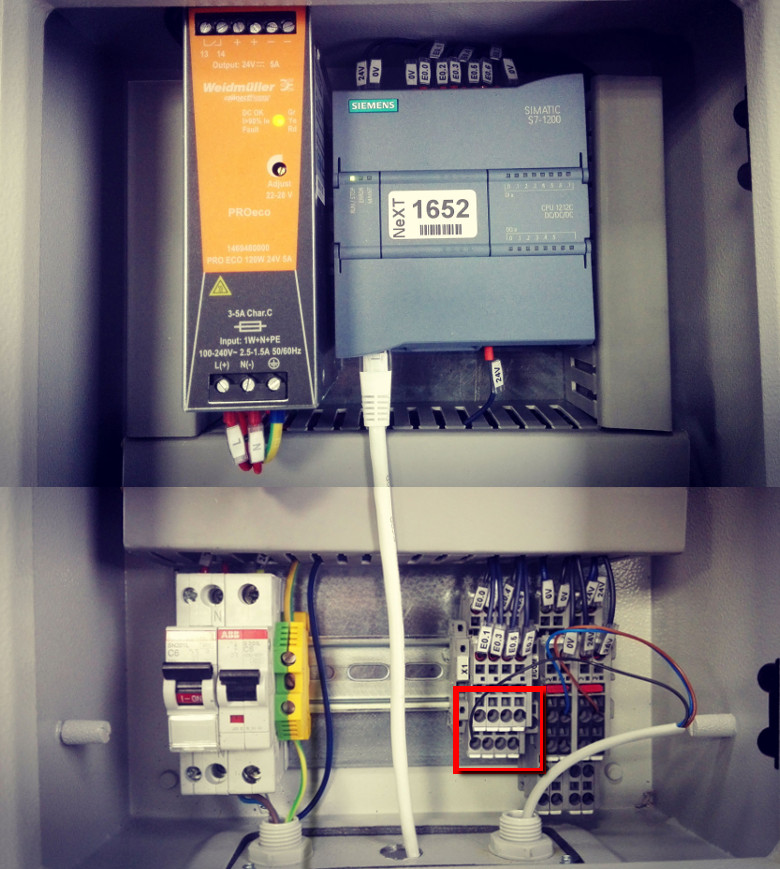

- A PLC

For each production line, there will be a touch panel and an LED TV (The Andon board).

The barcode reader connected to the touch panel will help the operator change the production order and, in case the PLC is missing, to increase the number of pieces produced.

The barcode reader is connected to the touch panel via a USB port, and the touch panel is connected to the system via ethernet cable.

The Mini PC is connected to the LED TV via an HDMI port and is also connected to the system via an ethernet cable.

The main difference compared to a line without a PLC concerns the signaling mode of the advancement of a piece: the PLC automatically sends a signal when the operator performs the last operation.

Another signal from the PLC indicates the status of the machine (Running/Not Running).

Each PLC can be connected to 4 machines as it is provided with 8 slots.

Interfaces

The LED TV (Andon Board)

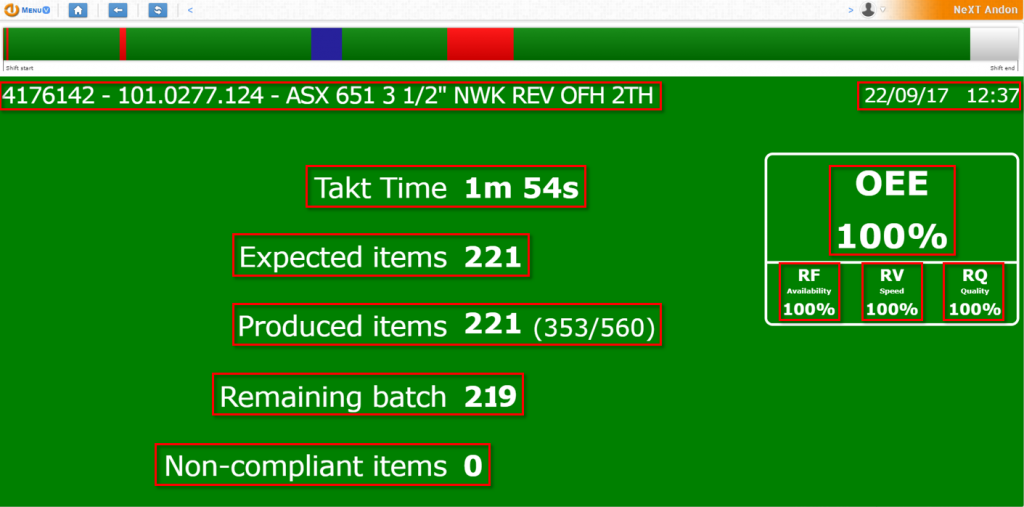

The Andon Board Interface

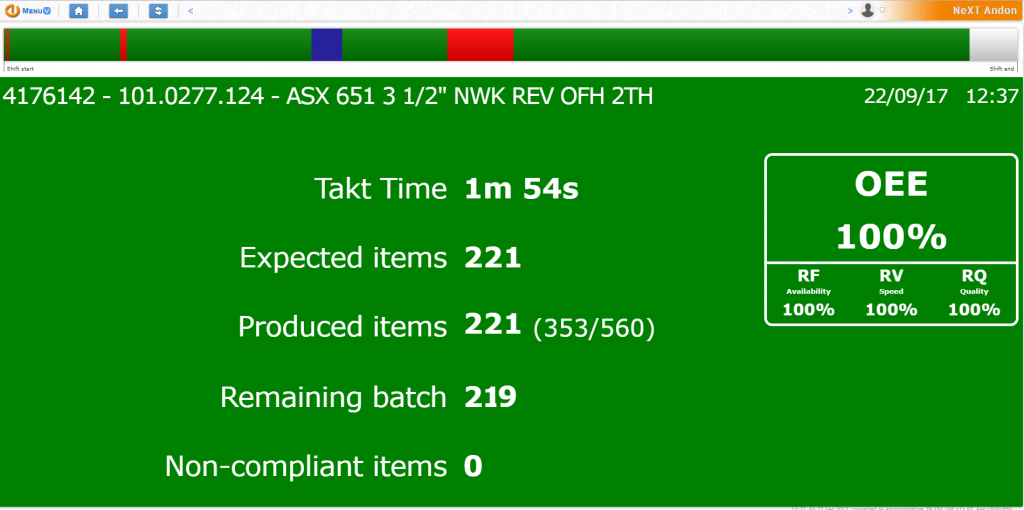

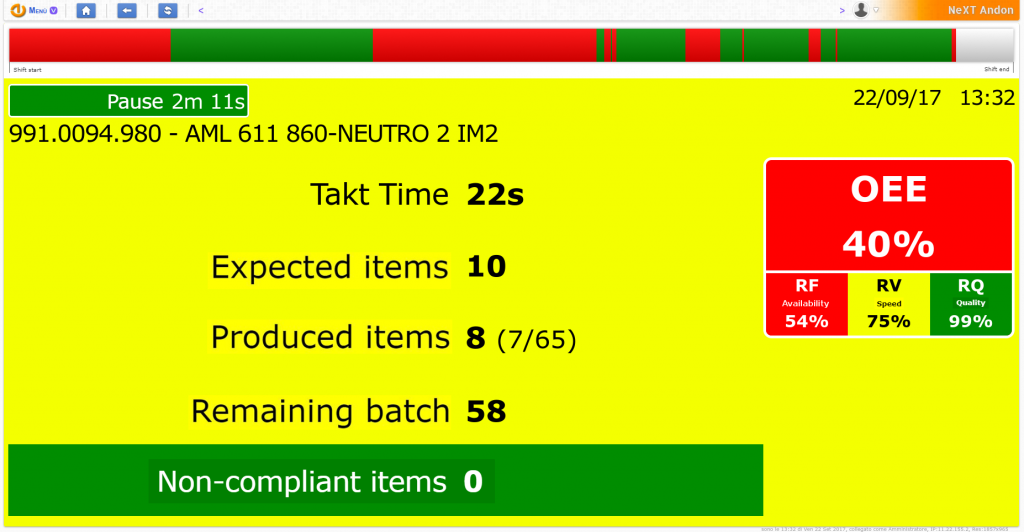

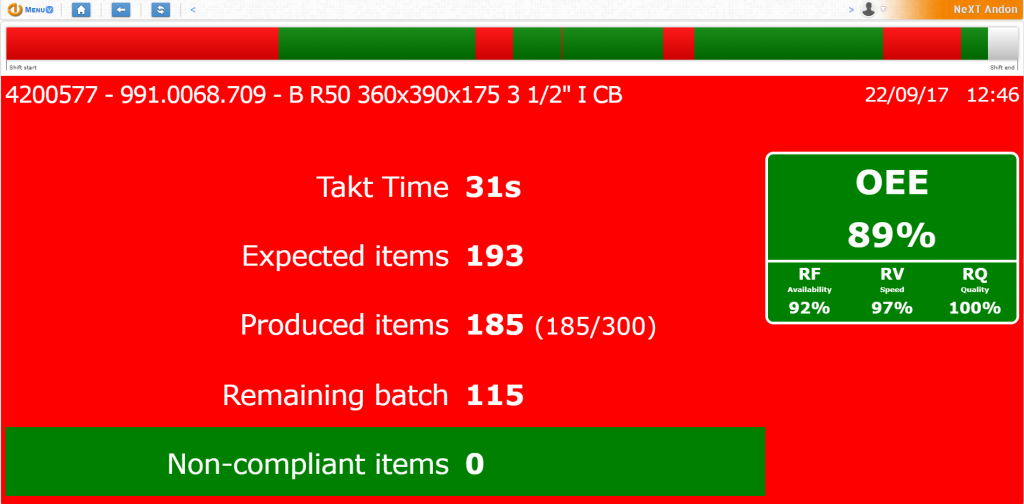

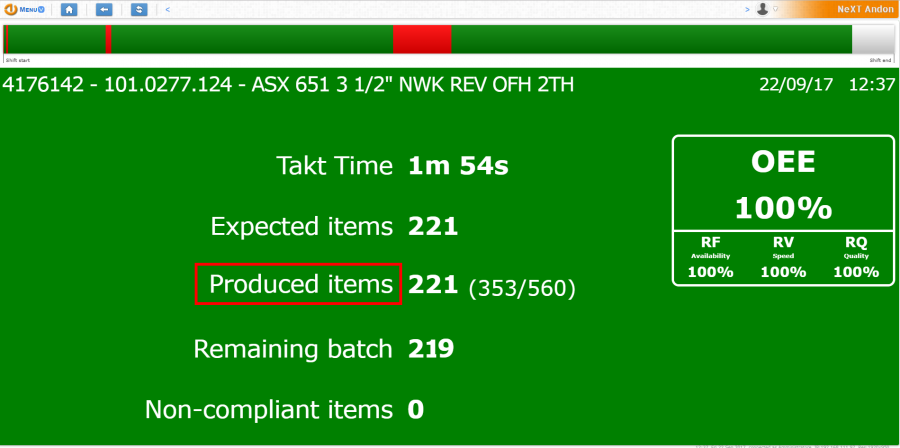

At the top of the page, a horizontal bar shows the sequence of stops of any type (programmed stop, maintenance stop, etc.).

In green, the runtime; in red the stop time, and in blue the scheduled stops.

Let's see the meaning of each element:

- At the top-left, there is the «Production Order code» currently ongoing.

- At the top-right, there is the date and time.

- Takt-time: is the time that each operator has to carry out its task.

- Expected items: it represents the theoretical production.

- Produced items: it represents the number of produced products, both goods and scraps.

- Remaining batch: the number of remaining pieces in order to complete the entire lot production.

- Non-compliant items: the number of parts not good (scrap items).

- OEE: on the right, there is the OEE value expressed as a percentage, referred to the current shift. Single percentages are also specified for availability, speed, and quality.

Even the colors of some elements have a specific meaning.

Green background: the background is green when the number of "Expected items" (for the current production) is equal to the number of "Produced items".

Yellow background: the background is yellow when the number of "Expected items" (for the current production) is greater by one or two items compared to the number of "Produced items".

Red background: the background is red when the number of "Expected items" (for the current production) is greater than the number of "Produced items" by three or more.

Also, the "Non-compliant items" area has its background color. Now we see the meaning of these colors.

- Green background: there were non-scrap items.

- Yellow background: there were one or two scrap items.

- Red background: there were three or more scrap items.

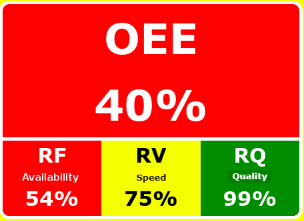

Also, the box that hosts the percentage of OEE will appear with different colors.

- Green: the percentage value is greater than 81%.

- Yellow: the percentage value is between 71% and 80%.

- Red: the percentage value is between 0 and 70%.

These percentage values can be customized line by line, so they may differ from those shown in this guide.

Likewise, the individual boxes of "Availability," "Speed," and "Quality" can take on different colors.

The Touch Panel

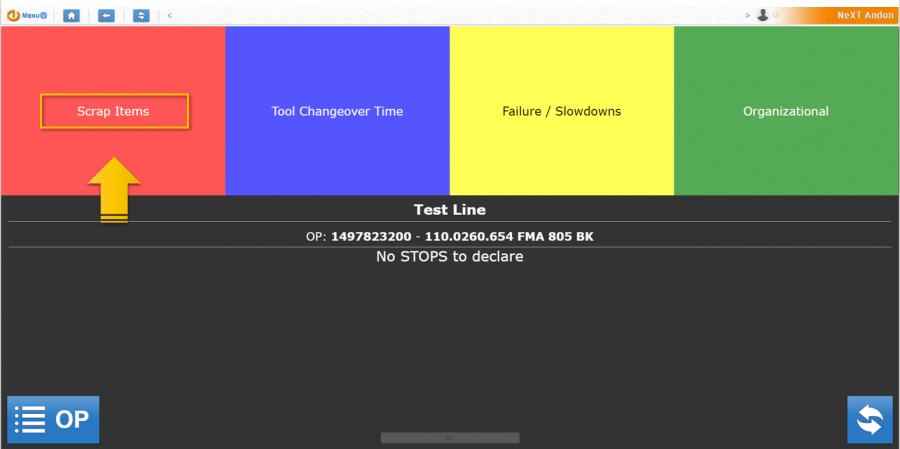

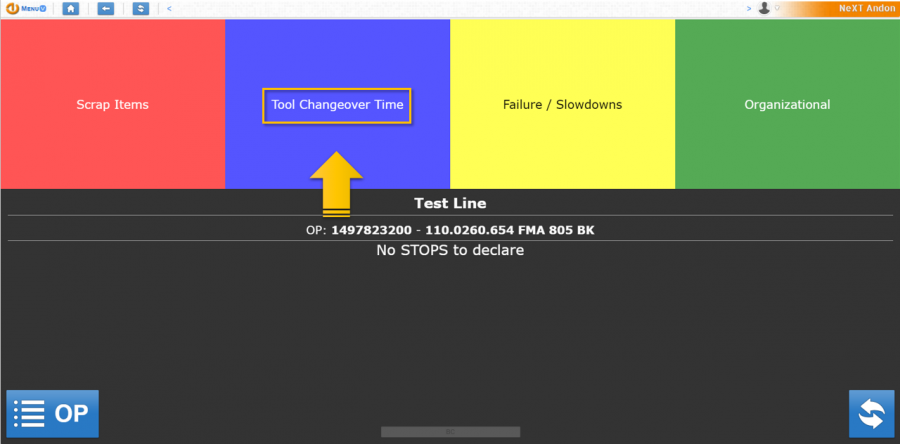

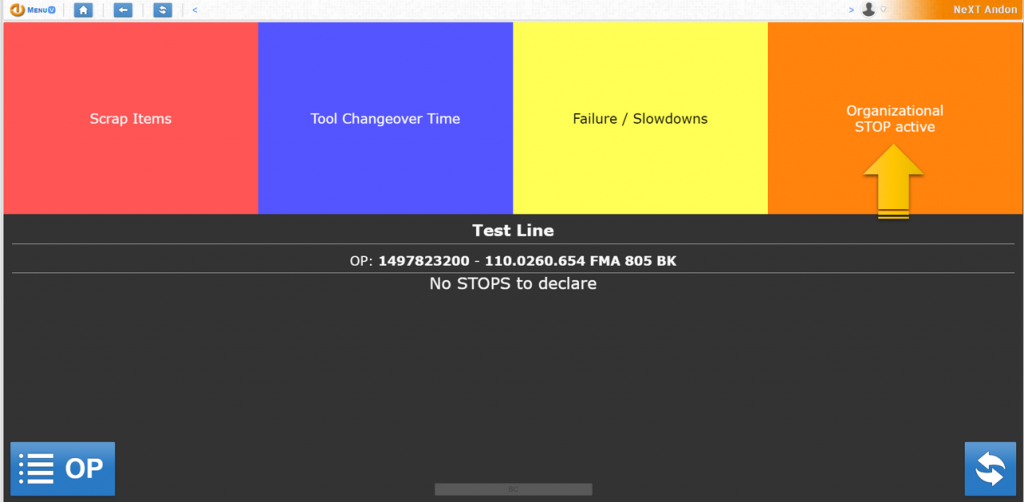

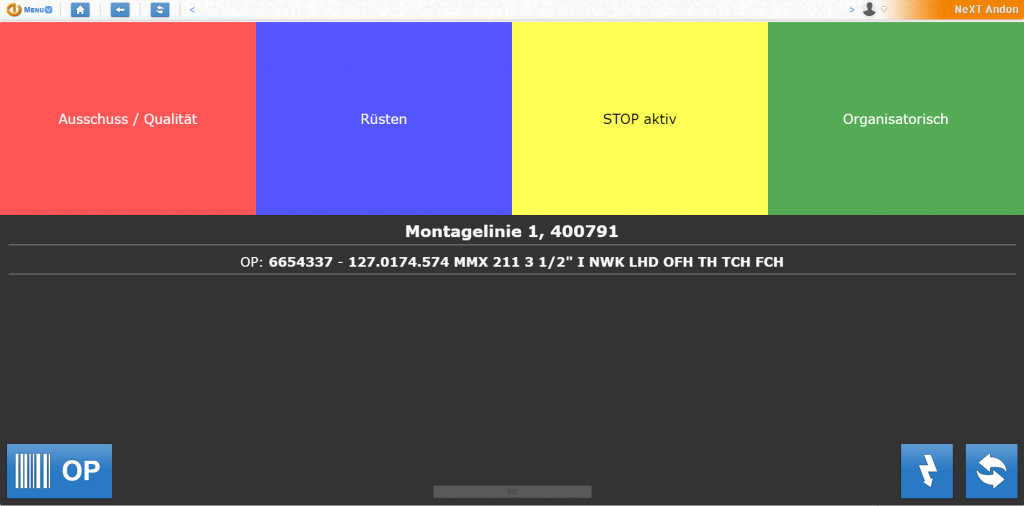

The Touch Panel Interface

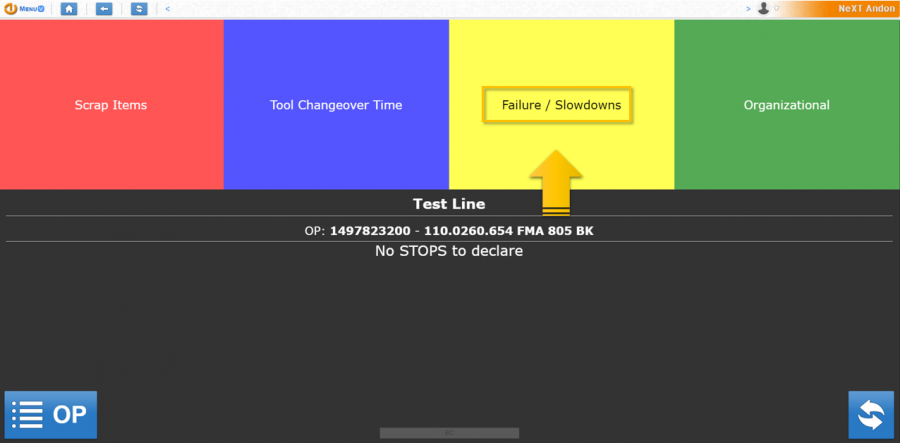

This is the interface of the touch panel.

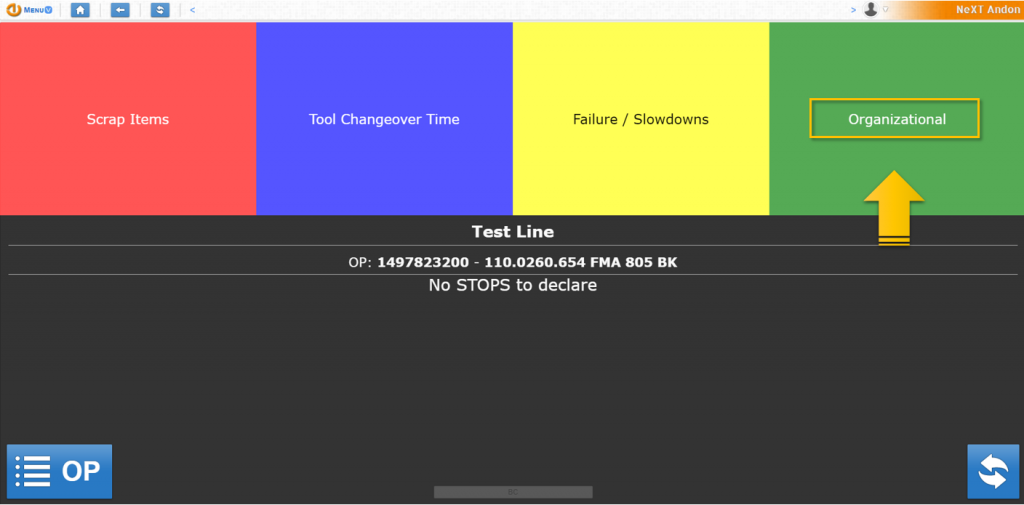

The red, blue, yellow, and green areas are buttons that allow the operator to access certain functions.

The "Scrap items" button provides access to a dialog box containing the datasheet of the quality loss causes. The operator must specify the appropriate cause.

For more information, see the paragraph "Declaring scrap."

The "Tool changeover time" button starts the setup process.

For more information, see unit "Tooling."

The "Failure / Slowdowns" button provides access to a dialog box containing the datasheets of the causes of the stops.

The operator must specify the appropriate cause.

For more information, see unit "Declaring stop for failure or slowdown."

The "Organizational" button provides access to some particular stop causes that have to concern organizational factors.

The operator must specify the appropriate cause.

For more information, see unit "Declaring stop for organizational cause."

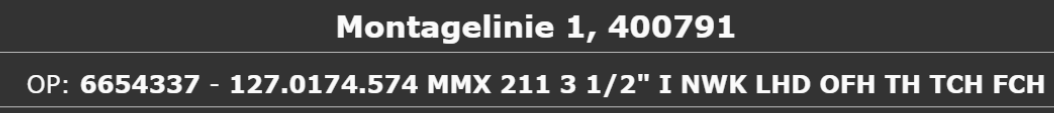

Below the four buttons, you can read the name of the line and the order of production that is processed at that time.

At the bottom left, there is the "OP button" that allows the operator to change the production order.

For more information, see unit "Production change."

At the bottom right, there is the "Flashing back" button that allows the operator to send the quantity of produced units and non-compliant items to SAP.

For more information, see unit "Flashback function."

Near the "Flashing back" button, there is the button to refresh the page.

Advancement of the Pieces

Here we'll show how to advance the pieces (with or without a PLC).

Without a PLC

As soon as the operator finishes all the operations, before moving on to the next piece, he/she will indicate the progress of the piece using the barcode reader, scanning the unique item number.

With a PLC

The main difference compared to a line without a PLC concerns the signaling mode of the advancement of a piece: it is the PLC that automatically sends a signal as soon as the operator performs the last operation.

The number of pieces will be updated on the Andon board (LED TV), under the heading "Produced items."

Declaring scrap

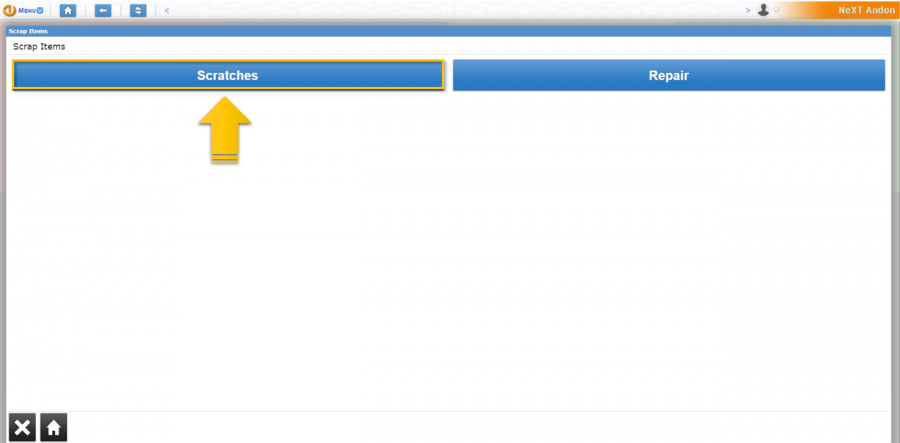

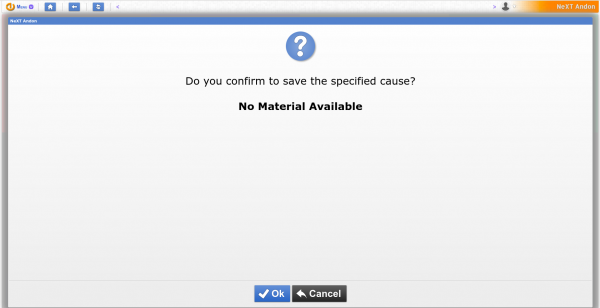

The following paragraph will show how the operator can declare the scrap items.

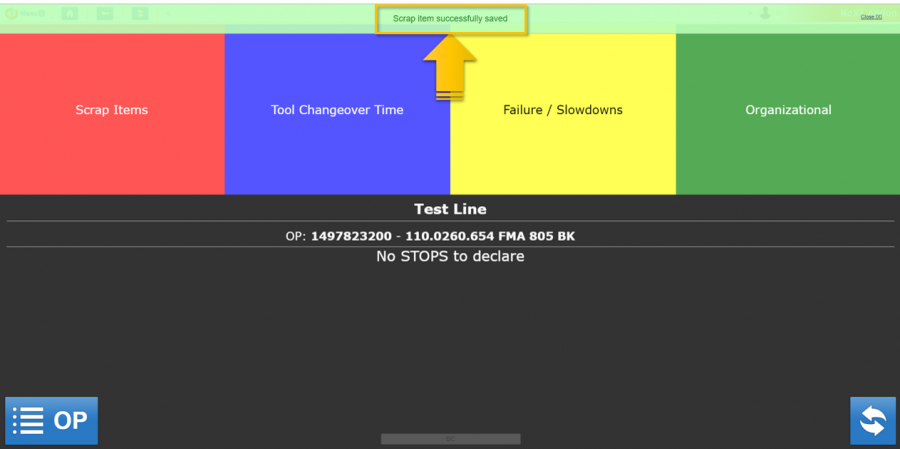

- Press the red area called «Scrap items»

- The operator has to choose from a list of causes

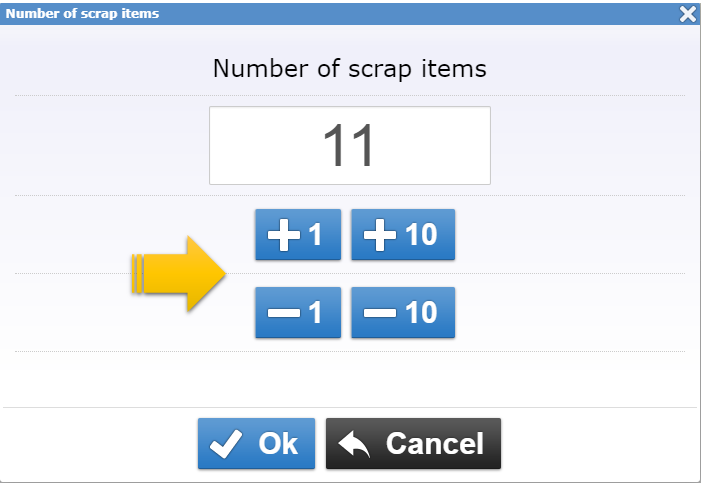

- Once the type of defect has been chosen, the operator can define the amount of pieces to be discarded

A message will inform the operator that the scrap declaration has been successful

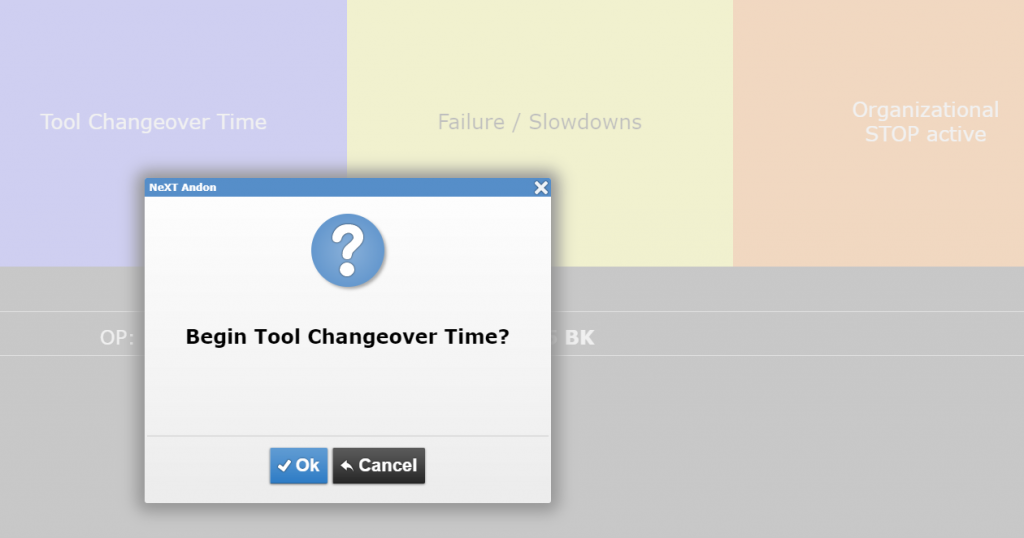

Tooling

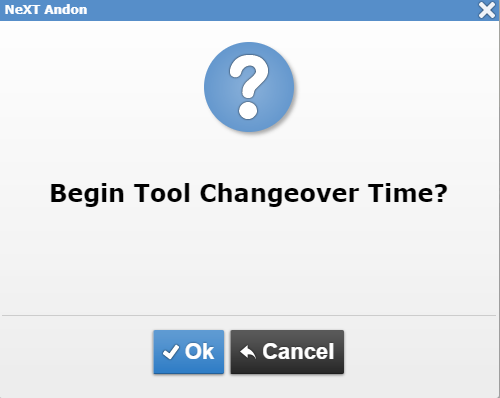

The following paragraph will show how the operator can start the tool changeover time.

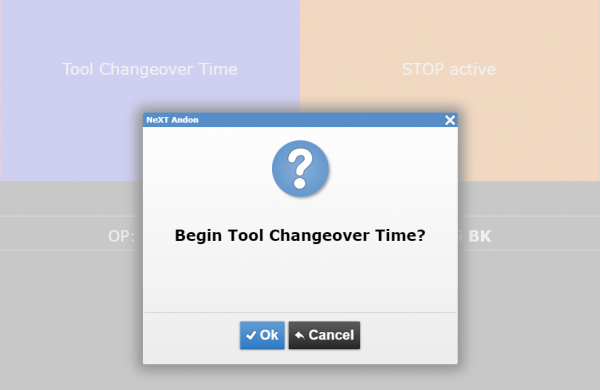

- Press the blue area called «Tool changeover time»

- The system will ask for confirmation of the choice to start the tooling

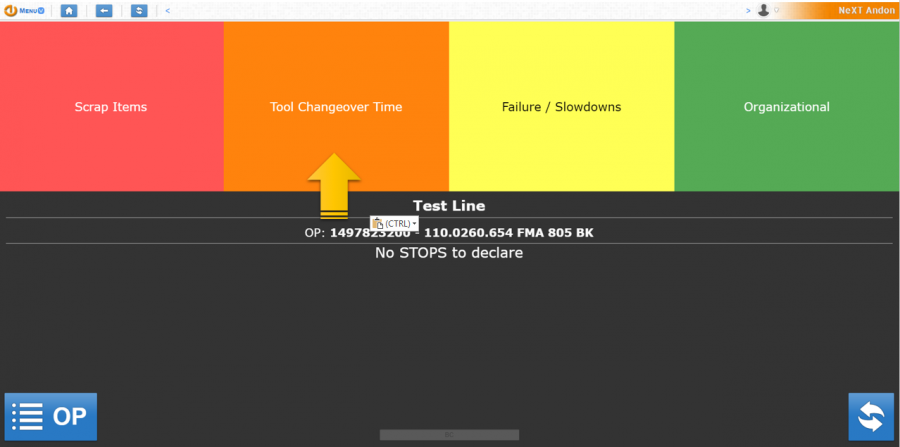

- Once the tooling has started, it will start blinking blue/orange for the entire duration.

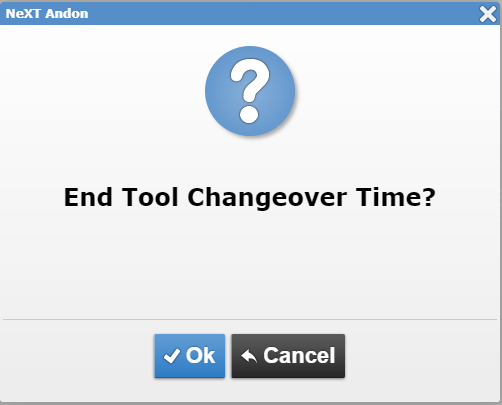

- Press the blinking area to end the tooling. The system will ask for confirmation.

Declaring stop for failure or slowdwn

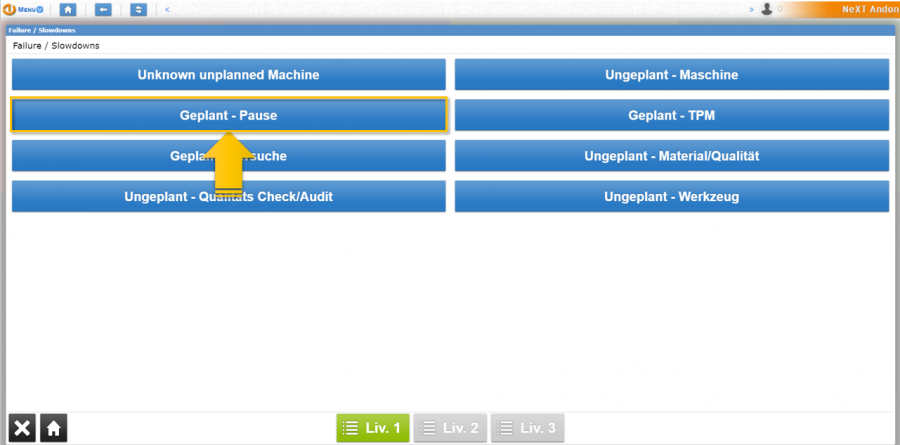

The following paragraph will show how the operator can stop the system for failure or slowdown

- Press the yellow area called «Failure/slowdowns»

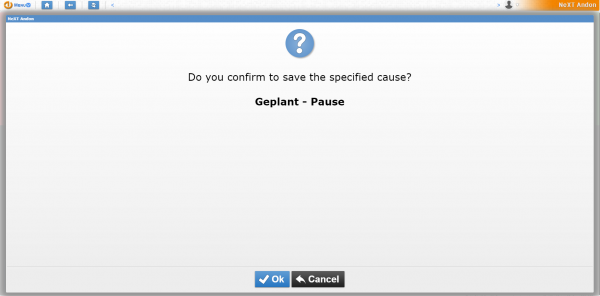

- The operator will have to choose the correct stop cause

- The system will ask for confirmation of the choice

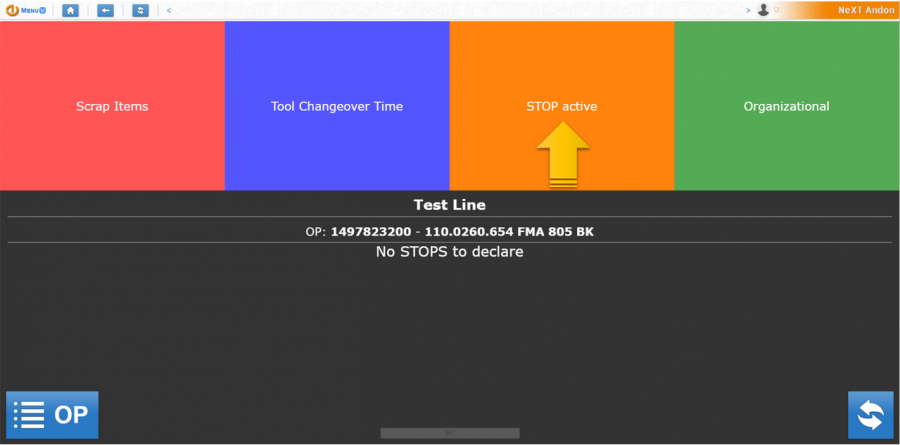

- Once the stop has started, it will start blinking yellow/orange for the entire duration

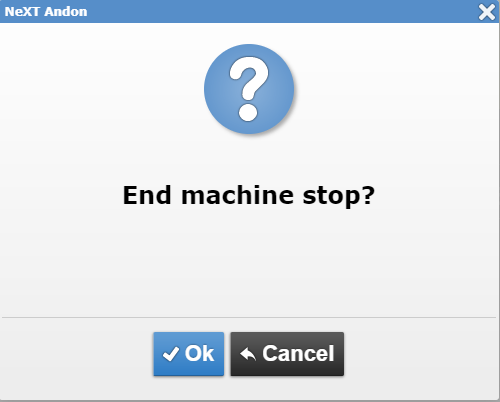

- Press the blinking area to end the stop machine. The system will ask for confirmation

- It’s also possible to switch from the stop machine, to tooling while stop is active

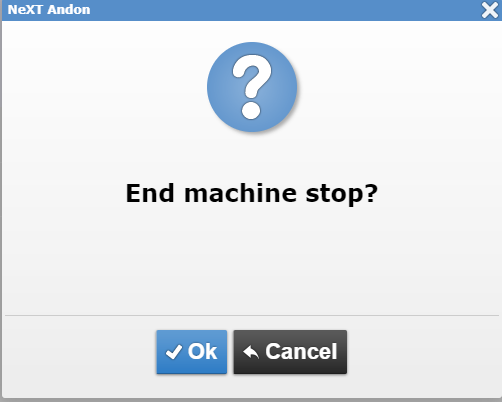

Declaring stop for organizational cause

The following paragraph will show how the operator can stop the system for an organizational cause

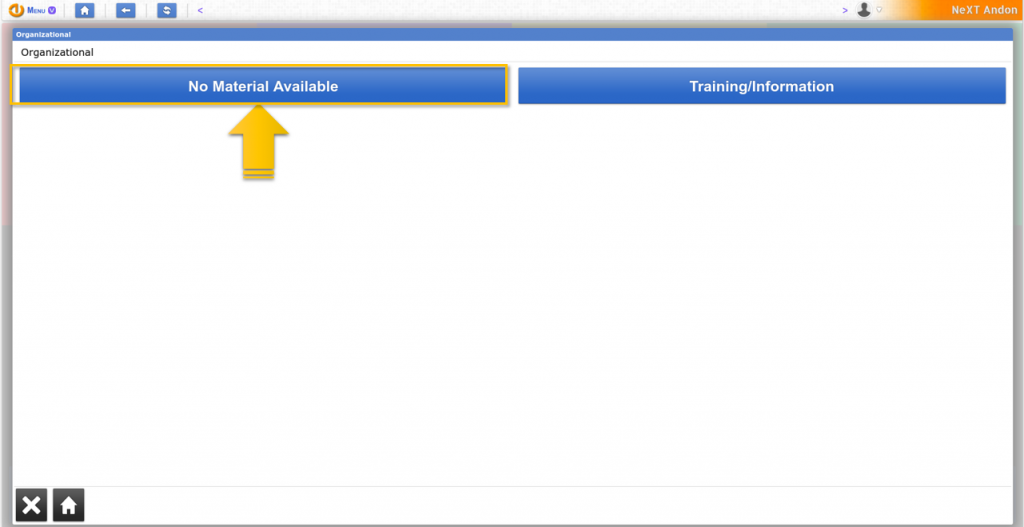

- Press the green area called «Organizational»

- The operator will have to choose the correct organizational stop cause

- The operator will have to confirm the choice

- Once the stop has started, it will start blinking yellow/orange for the entire duration

- Press the blinking area to end the machine stop. The system will ask for confirmation

- It’s also possible to switch from the stop machine to tooling while the stop is active

Production change

The following paragraph will show how to change a production

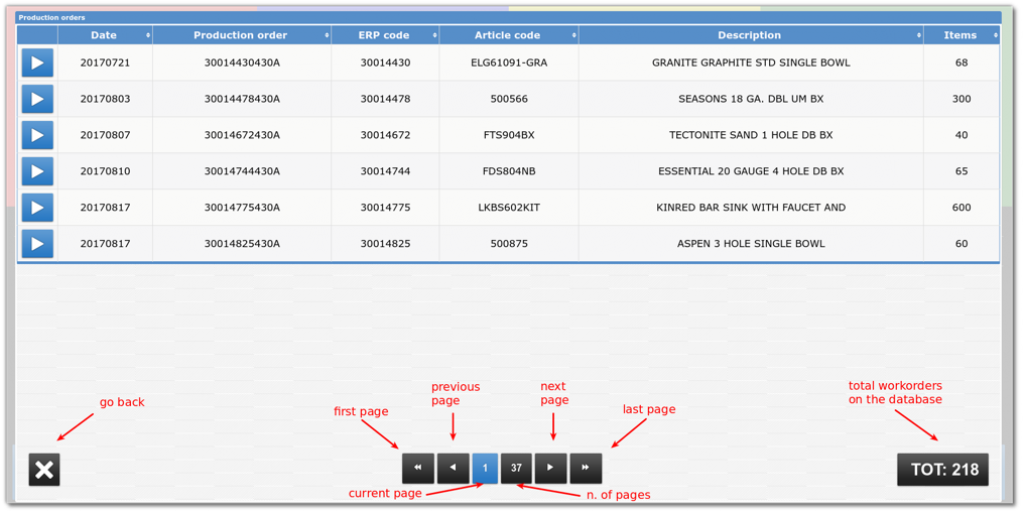

- Open the list of workorders and Press on the "OP" button to open the list. That list is sorted by release date in ascending order.

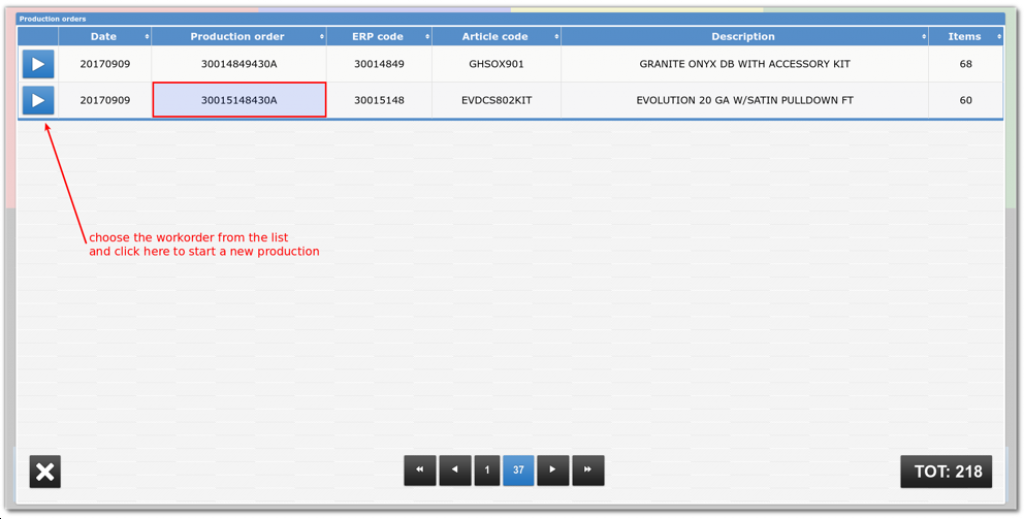

- Choose the workorder from the list. Use the buttons at the bottom to navigate.

- Press the "Play" button on the desired workorder to start a new production. A confirmation message will be shown.

- Verify information on the touch panel. The new production will be configured and the information about the selected work order, will be shown on the touch panel.

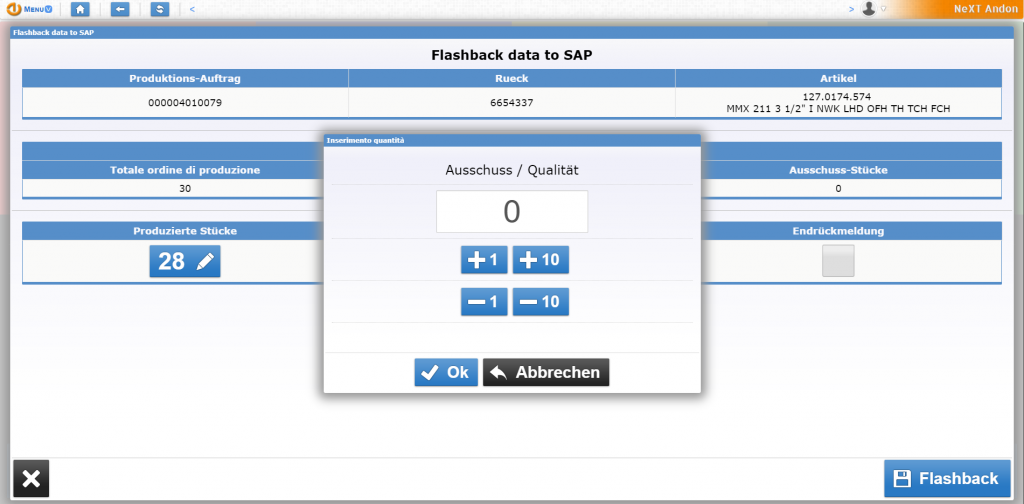

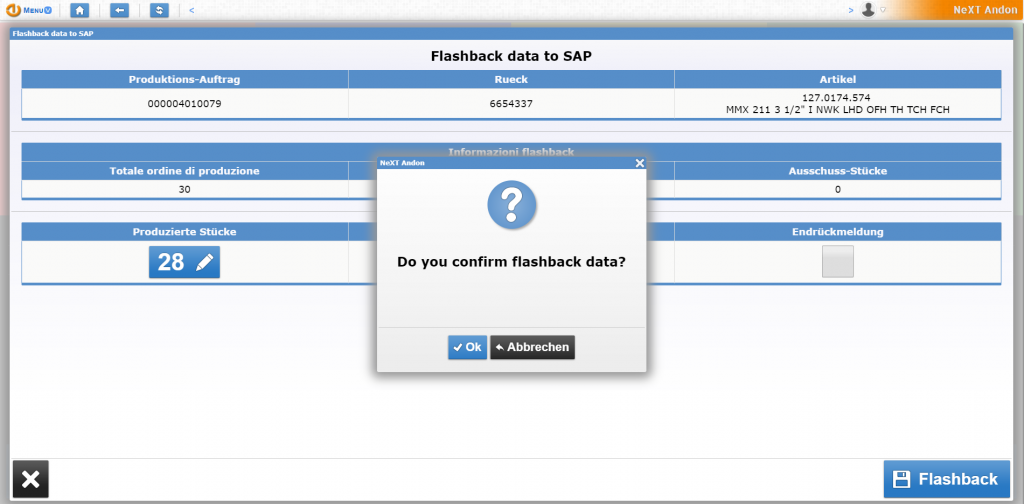

The falshback function

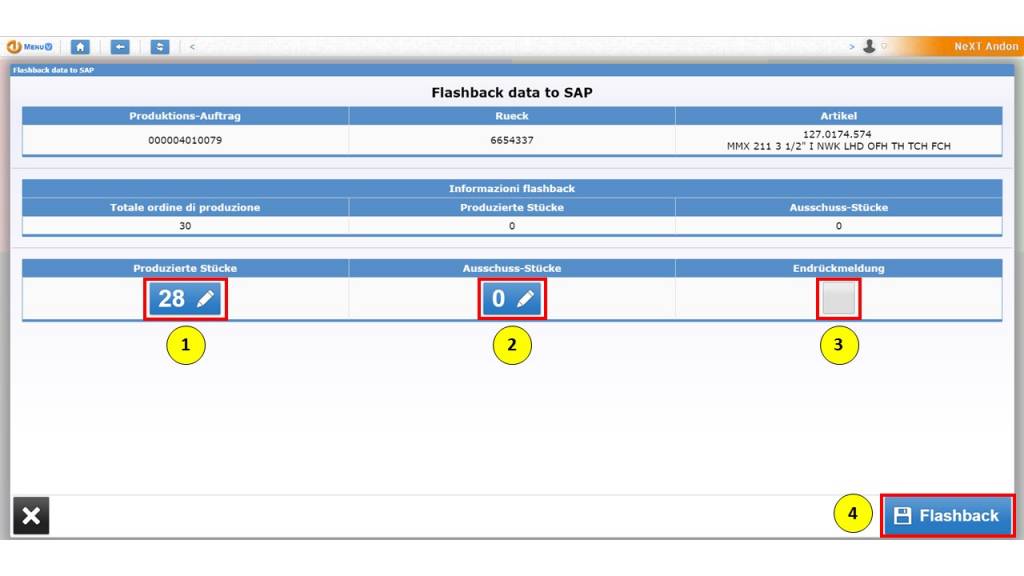

The flashback function allows the operator to switch to SAP, quantity of units produced and non-compliant items.

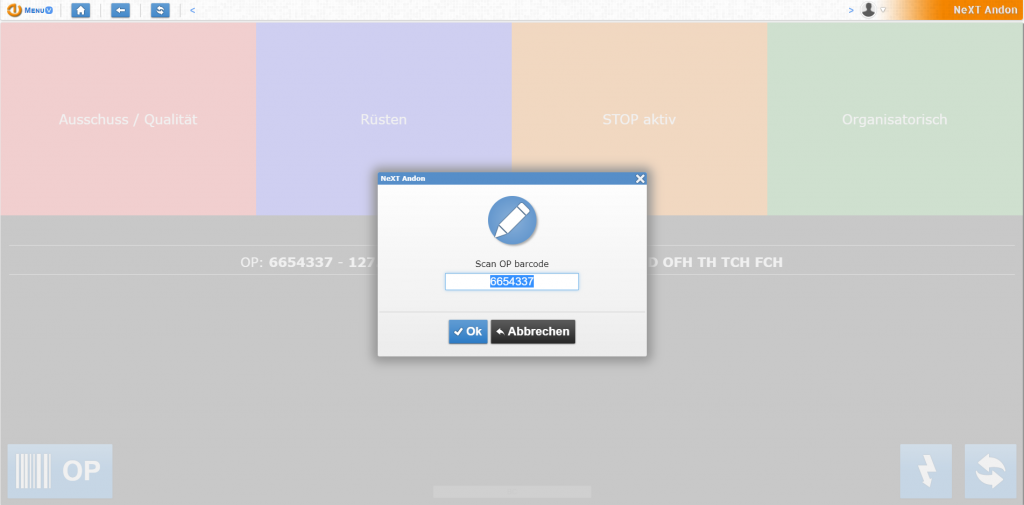

- Press the button at the bottom on the right, representing the icon of a lightning

- Enter the RUEK code. By default, the system proposes the current production code.

- From this screen the operator can communicate the quantity of units produced up to that time, and the quantity of non compliant items. The operator may also modify:

- the quantity of units produced (1)

- the amount of non compliant items (2)

- he can declare the order completed (3)

- finally, the operator must press the "Flashback" button at the bottom right (4)

- This is the screen to change the amount of units produced.

- This is the screen to change the amount of non compliant items.

- When the operator presses the "Flashback" button, the system asks for confirmation of the operation

Tracking maintenance

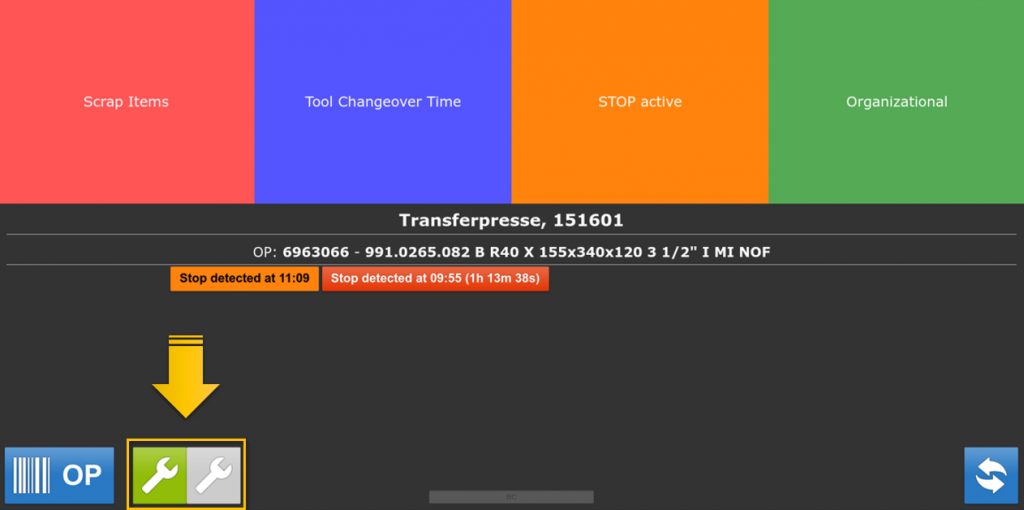

It's possible to track the maintenance during a stop machine.

When the resource has a stop machine running, two additional buttons will be shown.

The operator will press the green one with the wrench icon and then will confirm the choice.

Success / error message will be shown depending on the result of the operation.

Now, the green button become grayout (disabled) and the other button with the wrench icon becomes red: the operator has to press to end the maintenance.

The running stop machine remains as it is until the operator press the yellow blinking button “failure / slowdowns”.