Visual Management and touch panels view - through Agents

AgentVisual is an AgentBase that implements an ask for answering "Visual Management" requirements.

Shift Definition

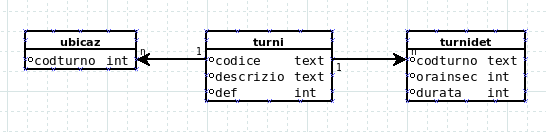

We should define before the "Shift definition" tables. Following tables schema

For identifying the shift we should use the tables TURNI and TURNIDEF. Each production line / machine should be mapped to shift code; table TURNIDEF defines details of each shift.

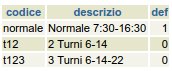

Following an example of table TURNI

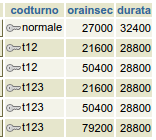

Following an example of table TURNIDEF

- TURNI.DEF=1 identifies the code of shift automatically assigned to each line that is not mapped explicitily to a shift;

- TURNIDET.ORAINSEC is the number of seconds from mind-night from which the shift begins

- TURNIDET.DURATA is the duration in seconds of the shift

Ask

Following a general schema for data required by a single line:

| Field Name | Field Description |

|---|---|

| codart | Product code |

| descrizio | Product description |

| codop | Work order |

| tm | Takt Time |

| npp | Number of pieces expected from the begin of the shift or from the begin of WO |

| np | Number of pieces produced from the begin of the shift or from the begin of WO |

| npt | Total of pieces produced for work-order |

| s | Number of scrapt items in the shift |

| oee | OEE in the shift |

| rf | RF, RV, RQ in the shift |

| rv | RF, RV, RQ in the shift |

| rq | RF, RV, RQ in the shift |

| state | State of line/machine (1=running/0=stop) |

| causafm | Cause of current stop |

| caudesc | Description of current stop |

| tmfm | TM of beginning stop |

| tpfm | Class of current stop machine F=generic stop,S=Setup,O=Organizational,P=Pause |

| npwo | Number of items required from WO |

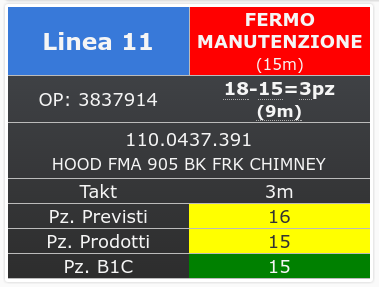

Data required from Visual TV

The following data refers to a specific production line / machine

| Field Name | Field Description |

|---|---|

| codart | Product code |

| descrizio | Product description |

| codop | Work order |

| tm | Takt Time |

| npp | Number of pieces expected from the begin of the shift or from the begin of WO |

| np | Number of pieces produced from the begin of the shift or from the begin of WO |

| npt | Total of pieces produced for work-order |

| s | Number of scrapt items in the shift |

| oee | OEE in the shift |

| rf | RF, RV, RQ in the shift |

| rv | RF, RV, RQ in the shift |

| rq | RF, RV, RQ in the shift |

| state | State of line/machine (1=running/0=stop) |

| causafm | Cause of current stop |

| caudesc | Description of current stop |

| tmfm | TM of beginning stop |

| tpfm | Class of current stop machine F=generic stop,S=Setup,O=Organizational,P=Pause |

| npwo | Number of items required from WO |

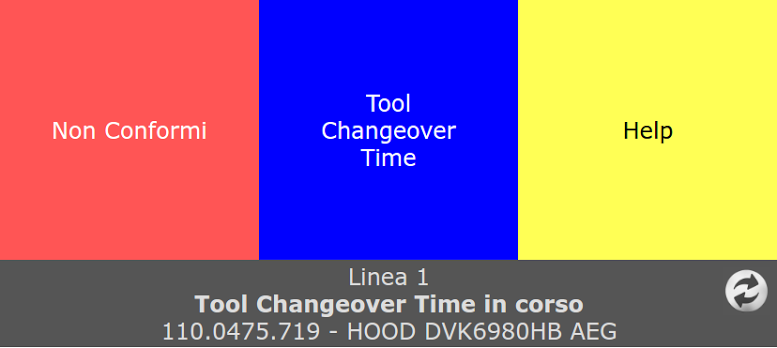

Data required from Visual Touch Panel

The following data refers to a specific production line / machine

| Field Name | Field Description |

|---|---|

| codart | Product code |

| descrizio | Product description |

| codop | Work order |

| state | State of line/machine (1=running/0=stop) |

| causafm | Cause of current stop |

| caudesc | Description of current stop |

| tpfm | Class of current stop machine F=generic stop,S=Setup,O=Organizational,P=Pause |

| tmfm | TM of beginning stop |

Data required from Visual Multi-Line

In this case we should have a row for each production line

| Field Name | Field Description |

|---|---|

| codart | Product code |

| descrizio | Product description |

| codop | Work order |

| tm | Takt Time |

| npp | Number of pieces expected from the begin of the shift or from the begin of WO |

| np | Number of pieces produced from the begin of the shift or from the begin of WO |

| npt | Total of pieces produced for work-order |

| s | Number of scrapt items in the shift |

| oee | OEE in the shift |

| rf | RF, RV, RQ in the shift |

| rv | RF, RV, RQ in the shift |

| rq | RF, RV, RQ in the shift |

| state | State of line/machine (1=running/0=stop) |

| causafm | Cause of current stop |

| caudesc | Description of current stop |

| tmfm | TM of beginning stop |

| tpfm | Class of current stop machine F=generic stop,S=Setup,O=Organizational,P=Pause |

| npwo | Number of items required from WO |

Other requirements

- Each production order should be changed and reworked in different time but in the same shift

- How we will manage multi-WO production ? We could use a JSON field containing information about WO ({wo:'xxx',codart:'yyy',descrizio:'kkk',npwo:'999'}

AgentVisualMng

AgentVisualMng has the aim to answer Visual Devices asks; it could have two type of asks:

- for giving information about a specific production line

- for giving information about a sub-set of production line (based on codubib)

- for giving information about all production line

In all cases the return value of the agent will be a IREC completed by all information required that are described in ask.

| Request | andonrt | |

|---|---|---|

| Data | Rec(codubi,codubib) | if codubi is not empty it queries a specific line, if codubib is not empty it queries specific department, if both are empty it queries all lines |

Following IREC information returned by AgentVisualMng for each request

| Field Name | Field Description |

|---|---|

| produbi | JSON: [{codop:'XXX',codart:'XXX',descrizio:'XXX',npwo:'999'},..] |

| tm | Takt Time |

| npp | Number of pieces expected from the begin of the shift or from the begin of PRODUBI |

| np | Number of pieces produced from the begin of the shift or from the begin of PRODUBI |

| npt | Total of pieces produced for PRODUBI |

| s | Number of scrapt items in the shift |

| oee | OEE in the shift |

| rf | RF, RV, RQ in the shift |

| rv | RF, RV, RQ in the shift |

| rq | RF, RV, RQ in the shift |

| state | State of line/machine (1=running/0=stop) |

| causafm | Cause of current stop |

| caudesc | Description of current stop |

| tmfm | TM of beginning stop |

| tpfm | Class of current stop machine F=generic stop,S=Setup,O=Organizational,P=Pause |

| npwo | Number of items required from PRODUBI |